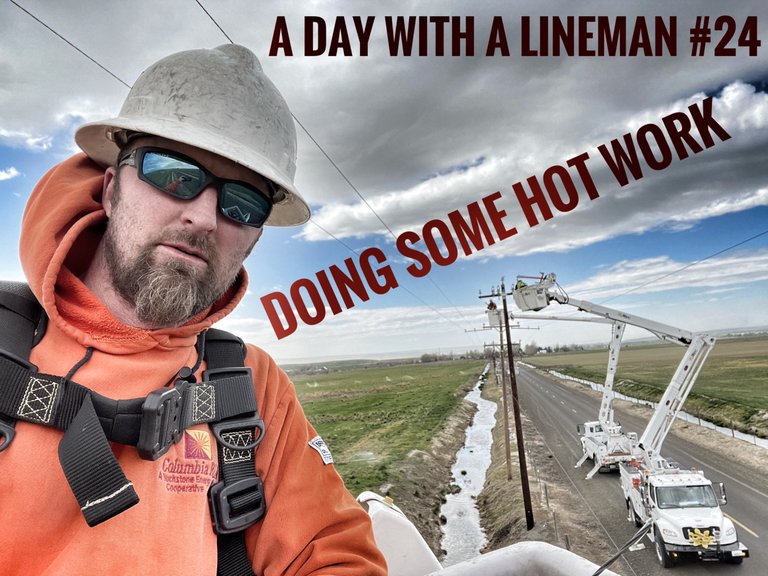

Certain times of the year we simply can’t de-energize the line to replace poles and string in new wire. Springtime is super important to the farmers around here. Their irrigation pumps are basically running non stop. To keep the customer’s pumps running but be able to change out old rotten poles and install bigger conductor we have a ton of Hot Work to do. Hot Work is when we use Hot Sticks to repair and move the powerlines energized. These hot sticks are typically 8 foot long, foam filled fiberglass sticks with many different attachments that can be installed on the end. They are tested yearly at 100,000 volts per foot wet. This line we are working on is a 14,400 volt line and thee wire is super old and small with several places having broken strands. Definitely not fun to work with but we take extra precautions in order to work this wire safely.

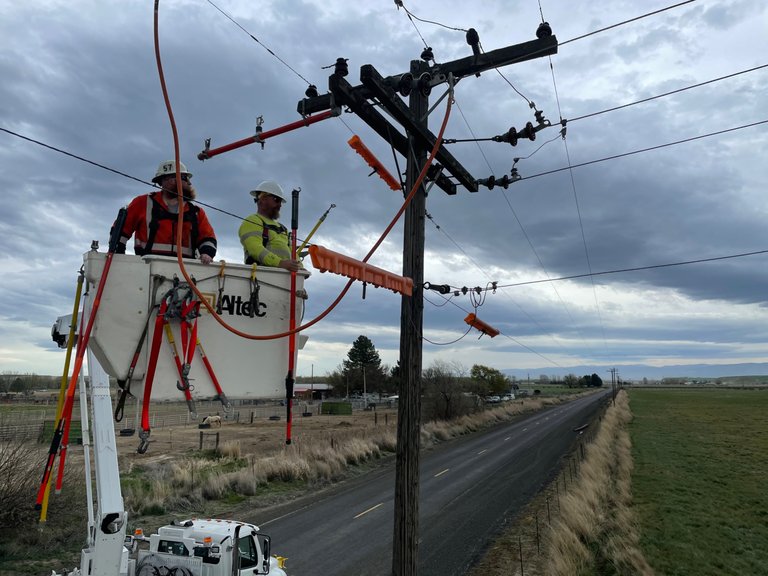

Of course once we were getting started the wind had to start blowing… go figure. When replacing poles and conductors while keeping the line energized, we have to spread the existing energized wire out onto Hot Arms. This provides a big gap in between the energized conductors to set new poles and pull new wire between them. It’s really time consuming and involves a ton of work but it keeps the customers happy.

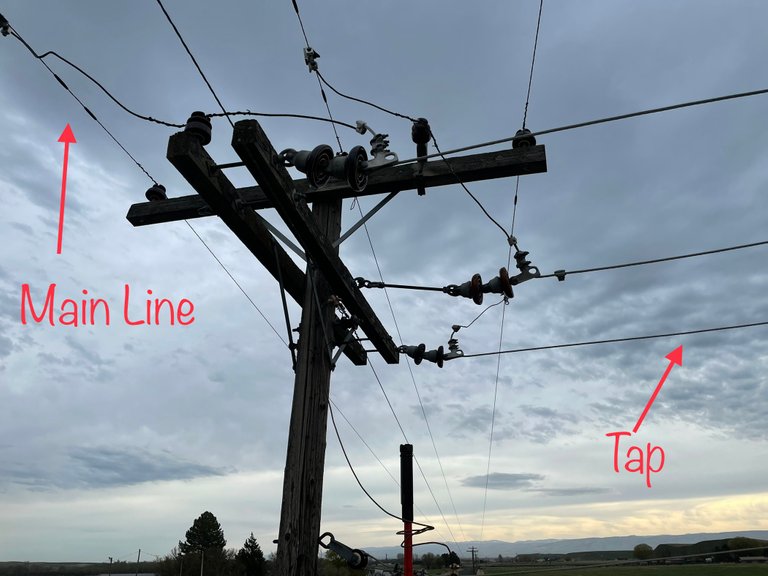

Most of the new poles aren’t going in the same place as the old ones, plus they are 10 feet taller. The straightline or tangent poles are pretty basic stuff for us. It’s when you have a tap off the mainline is when things get a little more complicated. Especially when the tap can’t be de-energized and instead of installing a taller pole to accommodate tractors, they cram everything really tight at the top of the pole.

By installing long insulated jumpers with Hot Sticks, we can cut the short copper jumpers out of the way. This allows us to move the main up and out where we need it while keeping the tap energized.

Insulated jumpers installed and ready to move wire after the new pole is set in between the energized conductors. We place insulated cover over the conductors while setting the pole, just in case of an accidental contact of the pole to the wire. Plus we wear Class II rubber gloves while setting a Hot Pole and never contact the pole with your body.

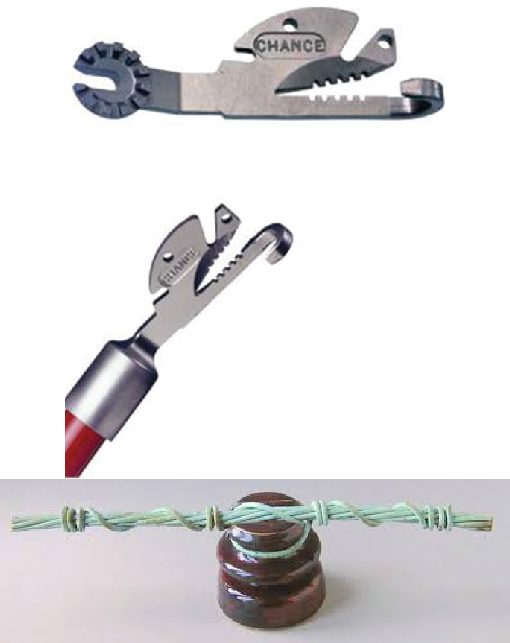

Two guys are in one bucket untying the wire from the insulators. The copper ties are #6 solid copper and were put on by hand when this line was first built. It’s wrapped around the insulator, over the top of the conductor, back around the insulator then wrapped tightly servers times on the conductor on both sides of the insulator. It takes lots of practice to become efficient at removing these thing. We typically use, what us Lineman call a Hand attachment to remove the ties.

source-source

After untying the wire we keep a close watch and help guid the wire to the new pole while the guy in the other bucket lifts it up and out onto the hot arms on the new pole.

The buckets have a winch with a 2 foot insulated pigtail stick on the end in order to pick the wire.

source

sourceSimply run the winch line down to the wire, hook the pigtail link around the wire and winch it up. Then smoothly fly the wire up and out into place. This old pole has to dry for the time being but it will come out eventually.

All three phases have been moved from the old pole up 10 feet and landing in the hot arms. This has to be done to all 27 poles on this job.

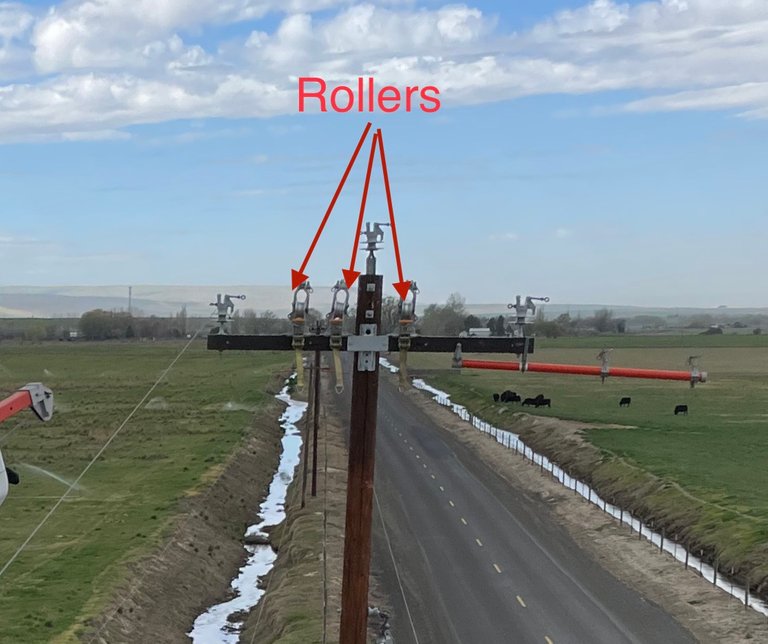

When it comes time to pull in the new wire, we will first pull in ropes. The ropes will go up the pole and through the rollers-travelers-dolleys, whatever a Lineman wants to call them, all the way down the line. Then one wire at a time will be pulled in.

Once the wire is in and to the proper tension, it’s placed on the insulators and secured with a tie or clamp. Then more Hot Work is done to energized the new conductor and de-energize the old conductor and get rid of it. We got a lot of work ahead of us to complete this job. I hope to bring you guys updates as the job moves along.

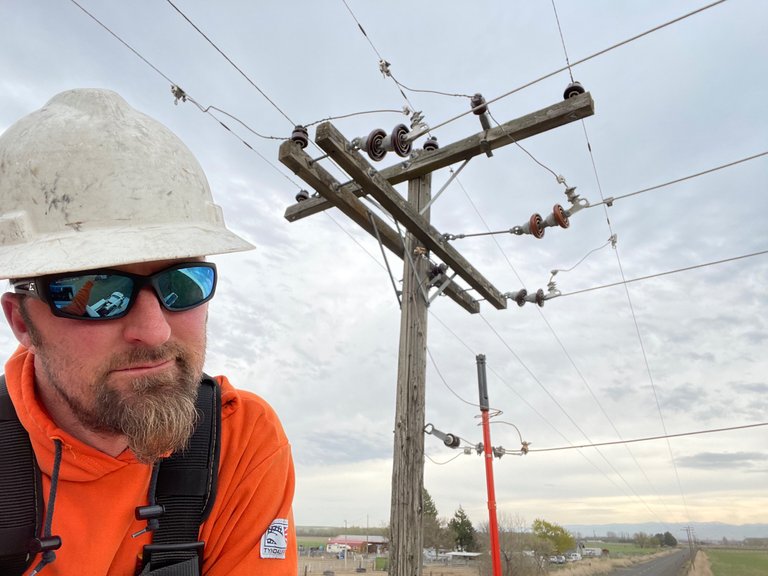

I hope you enjoyed this little inside look from your Hive Lineman about what we do to keep the lights on and irrigation pumps running for our customers. I’ve been in the trade for 17 years and love everyday of it… almost everyday. Stay safe out there and when you see the Linecrew give them a thumbs-up, a wave or a simple thank you. It overrides the many middle fingers we get. 😉

Your Random

Dose of...

Whoa! That's some work and very intense, I bet.

That 'hand' and all the attachments are really cool.

Stay safe up there..

I’ve been meaning to go through a handful of attachments and show how we use them but just haven’t got around to it yet.

Always!! Thanks for stopping by

That would be awesome